Notifications

6 minutes, 24 seconds

-2.9K Views 0 Comments 0 Likes 0 Reviews

If you’re a producer in the cannabis industry looking to scale up your pre-roll production, automation might be on your radar. But upgrading to automation is a major decision and expense, so how do you know when to take the leap?

Here’s a streamlined guide to help you decide if it’s time to automate and what to consider based on insights from the Pre-Roll Experts.

Assessing Production Needs

The decision to automate often starts with a simple calculation: comparing the monthly volume of pre-rolls you produce versus the labor costs involved in manual production.

Automated pre-roll machines, capable of producing thousands of pre-rolls per hour, become cost-effective when production reaches a significant volume. We don’t recommend upgrading to automation until your demand exceeds 50,000 pre-rolls monthly—a volume achieved by fewer than 10% of producers.

Choosing the Right Time and Type of Automation

Automation isn’t just about meeting production volumes; it also involves considering the types of products you’re creating.

If your product line includes multiple strains or varying pre-roll products, such as different sizes or types (like cones versus tubes), you might face challenges. Automated systems excel with consistent inputs and might struggle with variation, potentially increasing turnover time between batches.

If your products require frequent adjustments for making different SKUs within a single day, maintaining several tabletop cone filling machinesmight be more effective – and cheaper – than fully automating the process.

Pros and Cons of Pre-Roll Automation

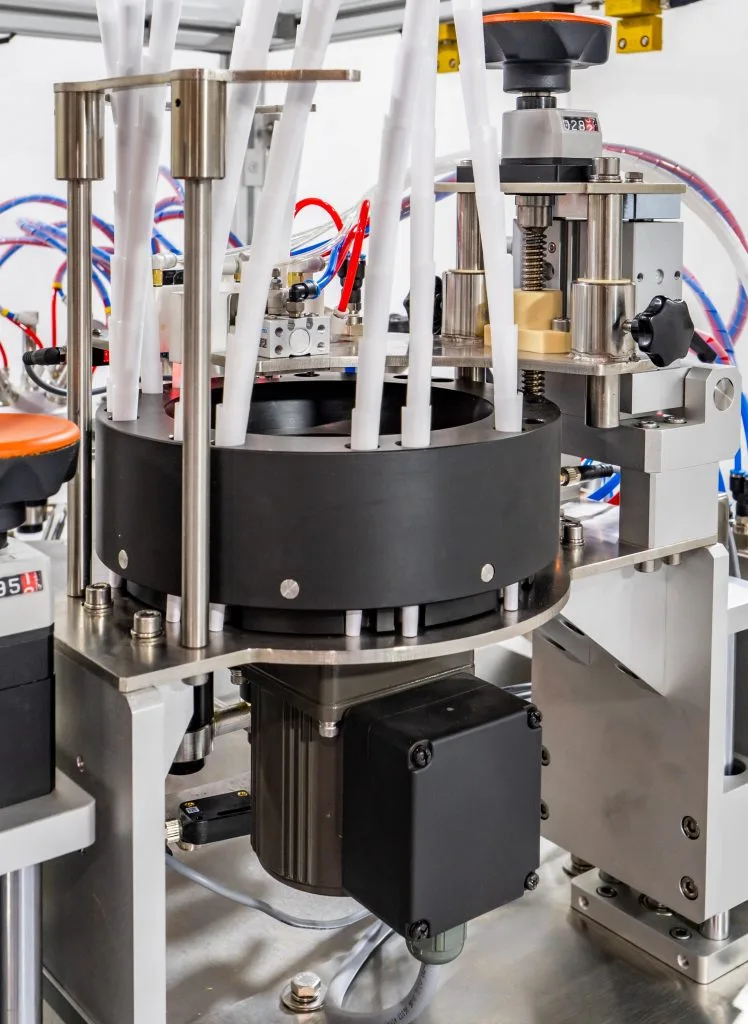

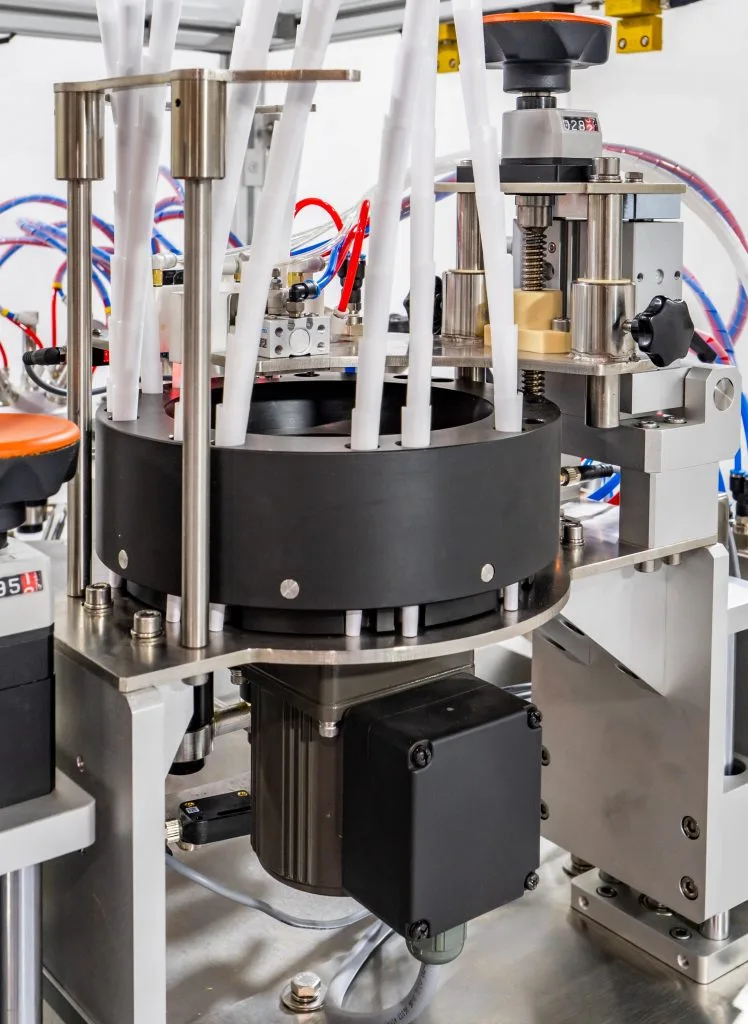

On the upside, automation can drastically reduce labor costs and improve consistency in product quality. Automated machines can handle tasks like filling, packing, and weighing with precision, potentially operating for hours with minimal human intervention. This efficiency can free up your workforce to focus on other aspects of production and packaging.

However, the transition to automation isn’t without its drawbacks. High initial costs can be prohibitive for smaller operations. Moreover, pre-roll machines require continuous monitoring and adjustments, debunking the myth of a “set it and forget it” solution.

Plus, the inherent variability in the stickiness and density of cannabis flower – not just strain to strain, but harvest to harvest – can make automated processing challenging, as machines prefer uniform inputs.

Automated pre-roll filling machines often also require additional training, so having a dedicated employee, potentially with an engineering background is helpful, so if your team has significant turnover, you may need to take the cost of re-training into consideration.

Other Considerations

There are a handful of other things to consider if you plan to automate your pre-roll production.

As mentioned, automated machines require a consistent particle size to work effectively, so if you do plan to upgrade to an automated pre-roll filling machine, it would behoove you to also have an industrial grinder and a sifter to ensure uniformity.

Manufacturers should also consider adding a humidor to their facility. Humidors provide a constant moisture level and storing ground flower helps maintain consistency of inputs before packing. Additionally, a humidor can be used to keep completed pre-rolls fresh prior to delivery at a dispensary, which is particularly helpful if you are producing large quantities.

Finally, make sure your pre-rolled cones are also consistent in their quality so they work in the automation process. The machine won’t realize if there are slight issues in the opening diameter or size of the cone and cannot adjust to make it work. Inconsistent, flimsy and other low-quality cones just aren’t going to be good enough to work with automated machinery.

Industry Trends and Growth

Understanding market trends can also help guide your decision. The pre-roll segment has seen substantial growth, driven by the lowering cost of cannabis and technological advancements in pre-roll manufacturing.

This growth indicates a robust market potential for pre-rolled products, suggesting that investing in automation could be a forward-thinking move if aligned with industry dynamics and consumer demand.

When to Automate Your Production

Deciding to automate your pre-roll production involves analyzing your current production capacity, market trends and the specific needs of your product line. While automation offers significant advantages in terms of efficiency and cost reduction, it requires careful consideration of the types and variations of pre-rolls you produce.

But with the right approach, automation can be a pivotal step in scaling your cannabis business to meet increasing market demands efficiently.

Business Cannabis Cannabis business Cannabiz B2B Automation PreRolls Cannabis industry Cones

We believe in the power of connections. Our platform is more than just a social networking site; it's a vibrant community where individuals from diverse backgrounds come together to share, connect, and thrive.

We are dedicated to fostering creativity, building strong communities, and raising awareness on a global scale.

Share this page with your family and friends.